Ciao bella, Aloha nani, Hello beautiful flower!, may we adorn our bodies in your essence, be whisked away by your seductive allure, your tantalizing scent that speaks volumes without words.

Some of you, precious flowers, bloom for only a day, a few glimpses that come and go, leaving behind you longing for more…begging a question – how can we make your presence last forever…

With that poetic opening I bring to you a glimpse into the magical world of aromatherapy. Magical because the process is indeed at times convoluted, mysterious and rather precious. It is believed that the Egyptians were the first ones to invent the distillation equipment, albeit crude, it opened a door to what will become a blooming industry over millennia.

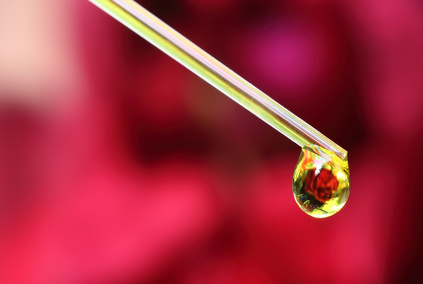

A rose by any other name, one drop is thousands of petals?

The Essential Oils

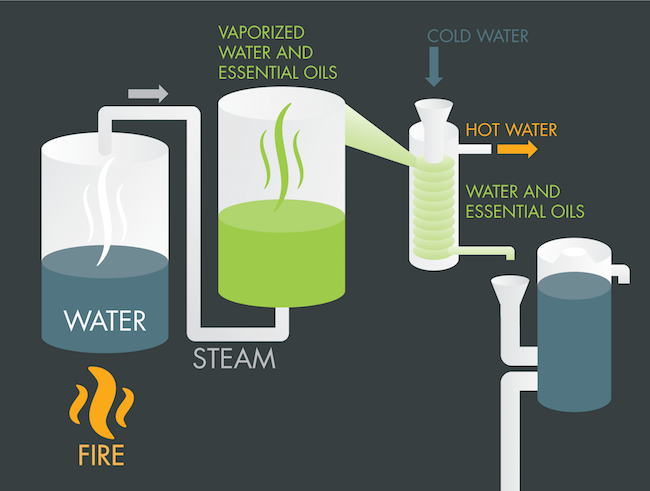

The essential oils are the most straightforward (thought by no means basic) category of aromatherapy. They are volatile (rapidly evaporating) fluids that are extracted from raw botanicals via the process of steam distillation. Essential oils can be extracted from the leaves, stems, roots, bark, flower or resin from a wide variety of botanicals, and can be used to create unforgettable experiences in perfumery and aromatherapy.

The steam distillation is achieved by passing a steam through a vat or hopper that contains raw plant materials. The steam causes the raw material to release their aromatic compounds that are present in tiny sacs or globules within the plant, which are then risen by the steam into a cooling system. The cooling process causes the steam to turn into water, thus separating it from the “oils” (though referred to as oils, are not actual fats). The steam converted into water will contain the water-soluble part of the plant and will become a floral water, also known as hydrosol (we will leave this for a later post)

The steam distillation is achieved by passing a steam through a vat or hopper that contains raw plant materials. The steam causes the raw material to release their aromatic compounds that are present in tiny sacs or globules within the plant, which are then risen by the steam into a cooling system. The cooling process causes the steam to turn into water, thus separating it from the “oils” (though referred to as oils, are not actual fats). The steam converted into water will contain the water-soluble part of the plant and will become a floral water, also known as hydrosol (we will leave this for a later post)

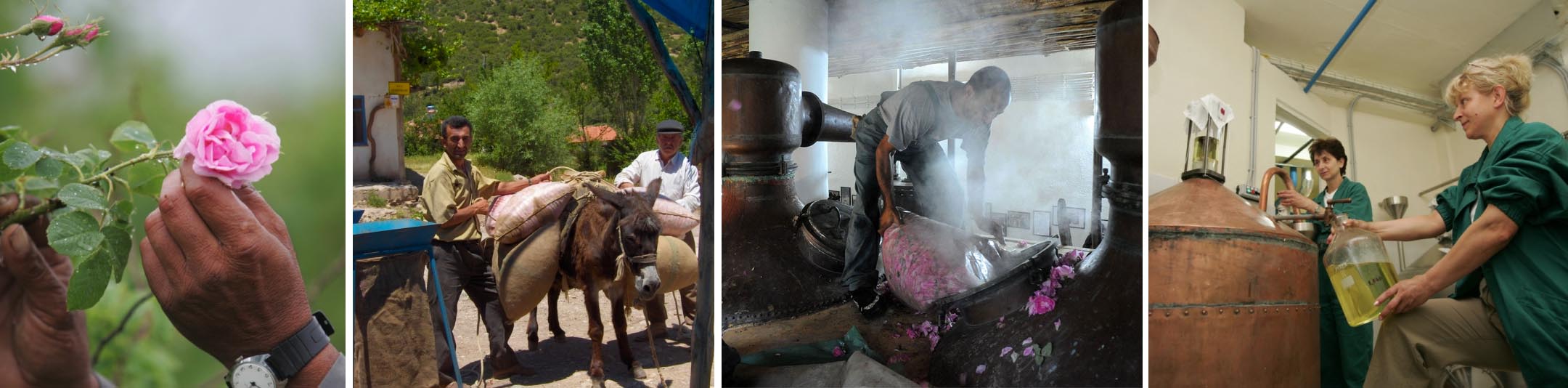

Seems pretty straightforward, doesn’t it. But, did you know that different botanicals, as well as varieties of the same botanical family, will require different amounts of raw material to produce the essential oil? Often the amounts of raw material required are gigantuous. For example: to produce 2 pounds of Damask rose essential oil (known as rosa damascena), steam distillers in Bulgaria will require near 8,000 pounds of rose petals. Or the sublimely refined and most delicate of the rose oils – Rose de Mai essential oil (known as May rose, or rosa centifolia), the steam distillers in France will require a staggering 20,000 pounds of May petals. Now think about this – an area of two acres will grow about 6,000 – 10,000 pounds of roses (during a good harvest season), which will in turn only produce 2 – 4.5 pounds of essential oil. Now think about how much that farm land is worth in France, Morocco, Bulgaria, Turkey etc. So you can start to imagine why the true and pure 1oz of rose essential oil is worth upwards of $350.

Lets pause and talk more about roses.

Did you know that there are over 5,000 varieties of roses, and that only two of them are used in aromatherapy? The harvesting of rose flowers is a backbreaking and detailed process. It generally takes place from mid-May to mid-June only. I remember when I was spending a summer in Bulgaria and Turkey in my younger days, I observed the rows of workers zooming to and fro the rose fields at sunrise, collecting the freshest flowers still covered with morning dew. Methodically, they give a sharp tug on the base of the rose so the petals remain intact. They then place the flowers in big bags tied to their belts. Each bag contains about 40lbs of roses. These bags, once full, are transported by the farm workers in vans, scooters or even muleback to the factory. Over hundred thousand pounds of rose petals get process at that factory in Turkey. They first get carefully spread on the ground, and then tossed in the air by pitchforks in order to guarantee the perfect ventilation and avoid possible fermentation. Flowers are then ready to be placed into the large vats or hoppers, which hold about 1,100lbs of petals and 1,400lbs of water to obtain the precious essential oil and rose water. Amazing, isn’t it?

The Absolutes

Creating a rose absolute, or any other absolute, requires a different process. In the 19th century southern France, the perfumers developed a technique called enfleurage, which combined animal fat with raw materials that were then pressed together between pieces of glass called chassis. This process took a few rounds of adding fresh raw materials until the fat was fully saturated with the desired aroma. The final result, the “enfleurage pomade”, was either used as is, or soaked in ethyl alcohol to draw the aromatics into the alcohol. The alcohol was then separated from the fat and allowed to evaporate, leaving behind the absolute of the botanical matter.

Nowadays, as more people tend to sway from the animal-based skin products, the enfleurage has been replaced by concretes. The concrete is made by combining raw materials with the solvent (often hexane, or ether), waxes or resins. To make rose absolute the rose petals are placed in alembics (vats) to which a solvent (liquid hexane) is added. After a few hours of washing, the solvent is removed by gentle heating in a vacuum, turning the mixture into a very fragrant concentrate, the concrete. This waxy compound is comprised of resins, waxes, high molecular weight botanical components and the low molecular weight aromatic compounds. It is then washed with ethyl alcohol, to draw in the aromatics, and put through a final distillation process to then completely remove the alcohol, leaving behind the extracted aromatic compounds, or the rose absolute.

The “naturalness” of this process is a topic of constant debate among aromatherapists, however we shall leave this for another post. One important point I’d like to add to the absolutes is that this process allows for a more bountiful production of oil. In this case to produce 1kg / 2.2lbs of Damask rose absolute, a factory in France will require only 2,200 pounds of petals. Compare that to 8,000 pounds of petals needed to make the same amount of essential oil by steam distillation.

Now, pick-up that little vial or rose oil (or if you don’t own one, I encourage you to take a tour to your local aromatherapy store at your earliest) and inhale it’s precious aroma, feeling the gratitude and appreciation to the people and process that brought you this delectable whiff.

——-

Psst – The Petal Mask features a luxurious line-up of rose essential oil, hydrosol and dried petals, paired with an aromatic and therapeutic ensemble of ylang ylang, jasmine,davana and more…

.